Technical Fundamentals of FPC Board Design

Comprehensive guide to FPC board technology. Explore flex circuit standards, material specs,

In the demanding realm of high-speed telecommunications and satellite technology, the PTFE PCB (Polytetrafluoroethylene Printed Circuit Board) stands as the definitive solution for high-frequency signal integrity.

Often recognized under the brand name Teflon PCB, these substrates are engineered to overcome the dielectric limitations of standard FR-4 materials. Leveraging 18 years of expertise in high-frequency material science, this article analyzes the physical characteristics and technical boundaries of PTFE laminates in precision electronic manufacturing.

The superior performance of a PTFE PCB is derived from its unique molecular structure. Unlike traditional epoxy resin boards, PTFE is a synthetic fluoropolymer characterized by its carbon-fluorine bonds—one of the strongest in organic chemistry.

Hydrophobicity and Moisture Resistance: PTFE substrates exhibit an ultra-low moisture absorption rate (typically <0.02%). This ensures that the board’s electrical properties remain consistent even in high-humidity aerospace or naval environments, preventing impedance fluctuations.

Reinforcement Structures: To improve dimensional stability, pure PTFE is often reinforced with woven glass fiber or ceramic fillers. This composite structure provides the necessary mechanical rigidity required for multi-layer PCB registration while maintaining the material’s excellent dielectric properties.

To ensure the reliability of microwave designs, engineers must evaluate the PTFE PCB based on the following industry-standard metrics (traceable to IPC-4103 standards):

Dielectric Constant (Dk) Stability

The Dk of PTFE laminates typically ranges from 2.1 to 3.5. For high-precision RF applications, a material like Rogers RT/duroid 5880 offers a Dk of 2.2 ± 0.02. Unlike standard materials, PTFE maintains this constant across a wide frequency spectrum (from 1GHz to 77GHz), which is critical for minimizing phase velocity variations.

Ultra-Low Dissipation Factor (Df)

Signal loss is the primary enemy of high-frequency circuits. PTFE PCBs offer a dissipation factor as low as 0.0009 at 10GHz. This level of energy efficiency ensures that high-power signals in radar and 5G base stations propagate with minimal thermal dissipation—a performance benchmark that is unattainable by FR-4.

Thermal and Dimensional Stability

High-quality PTFE laminates exhibit excellent thermal resilience. In thermal stress tests at 288°C, these boards show no delamination or blistering. Furthermore, the Z-axis Coefficient of Thermal Expansion (CTE) is controlled within 16–50 ppm/°C, ensuring the reliability of plated through-holes (PTH) during intensive thermal cycling.

One of the greatest challenges in PTFE PCB fabrication is the material’s naturally low surface energy (its “non-stick” nature). To achieve reliable copper bonding and solder mask adhesion, specialized surface modification is required:

Plasma Etching: The surface is treated with plasma to increase surface roughness and activate chemical bonding sites. This reduces the contact angle from 110° to below 40°, significantly enhancing the peel strength of the copper foil (typically achieving 8–12 lbs/inch).

Hole Wall Activation: Before the Electroless Copper process, a sodium-based etch or plasma cycle is mandatory to ensure the hydrophilicity of the hole walls, allowing for consistent plating in high-aspect-ratio vias.

The adoption of PTFE PCBs is strictly dictated by specific technical demands:

77GHz Automotive Radar (ADAS): The low-loss characteristics and precise Dk of PTFE enable the high-resolution object detection required for autonomous driving.

Satellite Communications (Satcom): In the vacuum and thermal extremes of space, the chemical inertness and low outgassing properties of PTFE ensure long-term mission reliability.

High-Speed Data Centers: As data rates exceed 112Gbps per channel, the ultra-low Df of Teflon PCBs is essential for maintaining signal eyes and reducing jitter.

Comprehensive guide to FPC board technology. Explore flex circuit standards, material specs,

Master Rogers PCB technology. Explore Dk/Df stability, RO4350B specs, and ISO 14644-1

Industrial PCB manufacturing experts: IPC Class 3 compliance, High-Tg substrates & 3oz+

- Pienten ja keskisuurten erien tuotannon asiantuntija

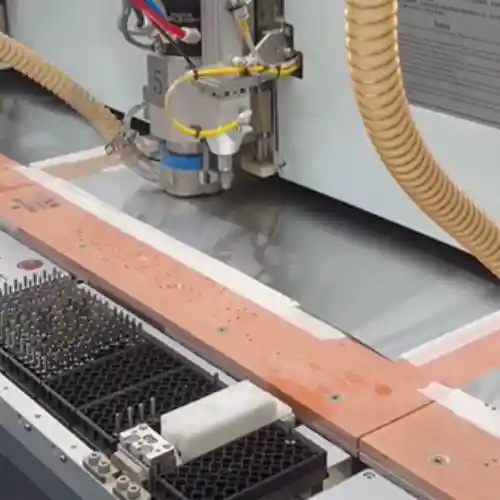

- Korkean tarkkuuden piirilevyjen valmistus ja automatisoitu kokoonpano

- Luotettava kumppani OEM/ODM elektroniikkaprojekteihin

Aukioloajat: (ma-la) klo 9:00-18:30.