Technical Fundamentals of FPC Board Design

Comprehensive guide to FPC board technology. Explore flex circuit standards, material specs,

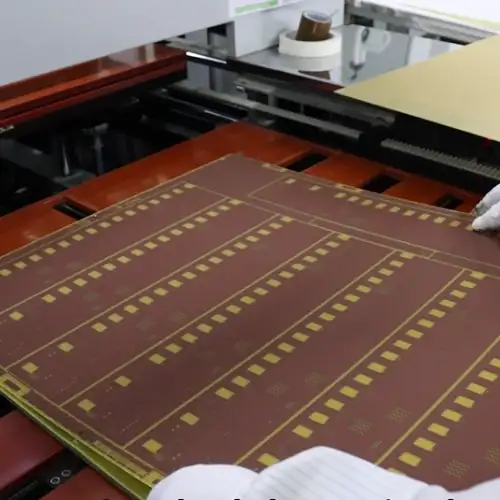

In the sector of industrial PCB manufacturing, the transition from prototype to mass production is governed by a singular priority: long-term reliability in harsh environments. Unlike consumer-grade electronics, industrial circuit board fabrication must support mission-critical infrastructure—ranging from power grids to robotic automation—where a single interconnect failure can result in catastrophic downtime.

The structural integrity of an industrial-grade printed circuit board begins at the molecular level of the substrate. Laboratory research into high-precision materials suggests that environmental stability is the primary driver of device longevity.

In industrial PCB fabrication, “quality” is not a subjective claim but a measurable adherence to international standards. The ISO 14644 standards for environmental control in cleanrooms are as critical for PCB etching as they are for precision component maintenance.

The IPC-A-610 Class 3 Difference

For critical industrial systems, manufacturers must adhere to IPC Class 3 rather than the standard Class 2.

The choice of an industrial electronic manufacturing service (EMS) depends on the specific environmental stressors of the target industry.

A professional industrial PCB manufacturer utilizes Design for Manufacturing (DFM) to maximize yield and minimize field failures.

Misconception 1: “Lowest Unit Price Equals Best Value”

Field data suggests that the Total Cost of Ownership (TCO) of a PCB is determined by its failure rate. A low-cost board that causes a factory shutdown can result in repair costs 100 times higher than the initial procurement price.

Misconception 2: “Standard FR4 is Suitable for All Industrial Uses”

In high-humidity environments (above 70% RH), standard FR4 is susceptible to Electrochemical Migration (ECM). Professional procurement should mandate the use of anti-CAF (Conductive Anodic Filament) materials to ensure the total number of microbial or chemical “colonies” on the board surface remains near zero.

Successful industrial PCB manufacturing requires a partner who treats every micron of copper with the same precision as a nano-scale optical lens. By integrating ISO 9001/14001 certified processes and IPC Class 3 reliability, we provide the interconnect solutions that keep modern industry running without interruption.

Comprehensive guide to FPC board technology. Explore flex circuit standards, material specs,

Optimize RF designs with PTFE PCB technology. Explore 2.1-3.5 Dk stability, 0.0009

Master Rogers PCB technology. Explore Dk/Df stability, RO4350B specs, and ISO 14644-1

- Pienten ja keskisuurten erien tuotannon asiantuntija

- Korkean tarkkuuden piirilevyjen valmistus ja automatisoitu kokoonpano

- Luotettava kumppani OEM/ODM elektroniikkaprojekteihin

Aukioloajat: (ma-la) klo 9:00-18:30.